Blank Welder Performance Qualification Record Form

Key takeaways

Filling out and using the Welder Performance Qualification Record (WPQR) form is essential for ensuring that welders meet industry standards. Here are some key takeaways to keep in mind:

- Accurate Information is Crucial: Always provide precise details, including the welder’s name, test number, and relevant specifications. Inaccuracies can lead to complications down the line.

- Understand Qualification Ranges: Familiarize yourself with the qualification ranges for different variables, such as base metal specifications and welding processes. This knowledge helps in determining the welder's capabilities.

- Mechanical and Non-Destructive Testing: Be prepared to document results from mechanical tests and non-destructive examinations. These results validate the quality of the welds performed.

- Certification is Key: Ensure that the record is signed by a Certified Welding Inspector (CWI). This signature confirms that the qualifications meet the required standards.

- Keep it Organized: Maintain a well-organized record of all WPQR forms. This practice not only aids in compliance but also provides a quick reference for future projects.

- Review Regularly: Regularly review and update the WPQR as needed. Changes in specifications or welding techniques may require new qualifications.

Common mistakes

Filling out the Welder Performance Qualification Record form can be straightforward, but several common mistakes can lead to issues. One frequent error is leaving out the Welder’s Name. This information is essential for identifying the individual who completed the qualification. Without it, the record may not be valid.

Another mistake involves incorrectly entering the Social Security Number. The SSN must be accurate to ensure proper documentation and verification. A simple typo can cause significant problems in record-keeping.

People often forget to include the Test Number and the Reference WPS Number. These numbers are crucial for tracking the specific tests conducted and ensuring compliance with the appropriate welding procedures. Omitting them can create confusion and hinder the qualification process.

Additionally, many individuals overlook the importance of specifying the Welding Process and Type. This section must clearly indicate whether the process is manual, semiautomatic, or automatic. Inaccuracies here can lead to misinterpretations of the welder's capabilities.

Another common error is failing to indicate whether Backing was used. This detail is significant because it affects the quality and integrity of the weld. Not specifying this can result in misunderstandings about the welding conditions.

When it comes to the Base Metal Specification, individuals sometimes neglect to provide the correct P or M numbers. These specifications are vital for ensuring that the right materials are used and that the welding process meets industry standards.

People may also forget to fill out the Deposited Weld Metal Thickness section accurately. This information is necessary for assessing the weld's strength and performance. An incorrect measurement can compromise the entire qualification.

Lastly, many individuals do not double-check the Visual Inspection results. It is crucial to confirm whether the weld passed or failed and to provide reasons for any failures. Neglecting this step can lead to misunderstandings and potential safety issues.

Misconceptions

Here are five common misconceptions about the Welder Performance Qualification Record (WPQR) form:

- The WPQR is only for certified welders. Many believe that only certified welders need to complete this form. In reality, it is essential for all welders, regardless of certification status, to document their qualifications.

- Completion of the WPQR guarantees job placement. Some assume that having a completed WPQR will automatically secure them a welding position. However, while it demonstrates qualifications, employers consider various factors during the hiring process.

- The WPQR is a one-time requirement. Many think that once they complete the WPQR, they never need to do it again. In fact, welders must update their records whenever they learn new techniques or work with different materials.

- All sections of the WPQR must be filled out for it to be valid. Some individuals believe that every section is mandatory. While most sections are important, certain variables may be marked as non-essential, allowing for some flexibility in completion.

- The WPQR is only relevant for structural welding. There is a misconception that this form applies solely to structural welding. In truth, it is applicable across various welding disciplines and industries, including pipe welding and fabrication.

Dos and Don'ts

When filling out the Welder Performance Qualification Record form, attention to detail is crucial. Here are nine important dos and don'ts to keep in mind:

- Do ensure all personal information is accurate, including the welder's name and Social Security number.

- Don't leave any sections blank unless specifically indicated as optional.

- Do double-check the reference WPS number to ensure it matches the welding procedure specification.

- Don't forget to specify the type of welding process being used, such as manual or automatic.

- Do indicate whether backing was used, as this can affect qualification.

- Don't overlook the importance of documenting the filler metal specification and classification numbers accurately.

- Do record the results of any mechanical tests conducted, including the type and figure number.

- Don't skip the visual inspection section; it is vital for confirming the quality of the weld.

- Do ensure that all signatures are present, including those of the certified welding inspector and the individual conducting the tests.

Following these guidelines will help ensure that the form is completed correctly and meets all necessary requirements.

Other PDF Forms

Job Application in Spanish - List your most recent job experience first when detailing work history.

Understanding the nuances of a loan agreement is crucial for both borrowers and lenders, as it helps prevent misunderstandings and disputes in the future. To ensure a smooth transaction, utilizing resources like California PDF Forms can provide guidance and templates that adhere to legal standards.

Pt Observation Hours - Make copies for your personal records as needed.

Discharge Upgrade to Medical Retirement - This form is used by veterans to seek changes to their service records.

Detailed Guide for Writing Welder Performance Qualification Record

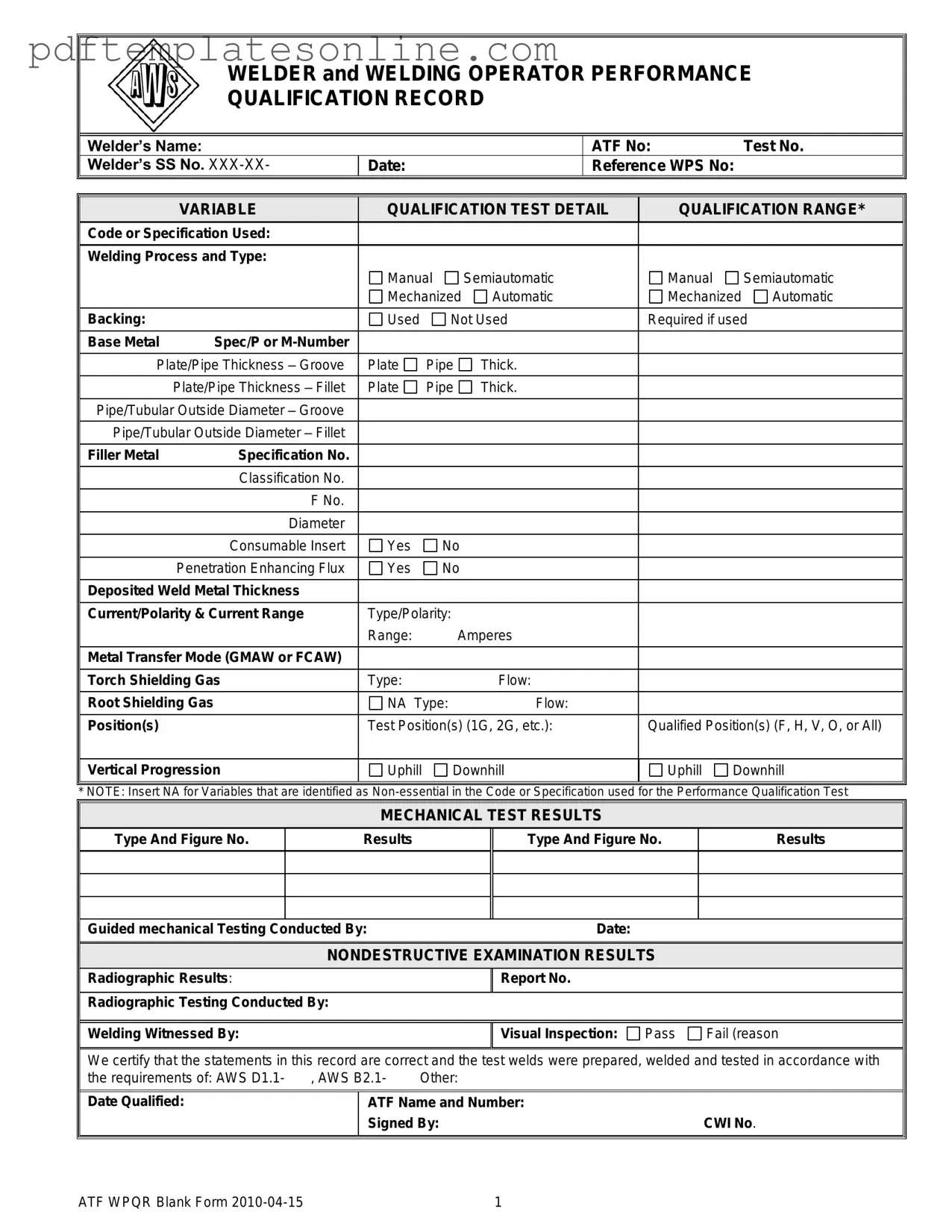

Completing the Welder Performance Qualification Record form is an essential step in documenting a welder's skills and qualifications. This form captures various details about the welder, the welding process, and the results of the qualification tests. To ensure accuracy and compliance, follow these steps carefully.

- Begin by entering the Welder’s Name at the top of the form.

- Fill in the ATF No and Test No in the designated fields.

- Provide the Welder’s SS No (Social Security Number) in the appropriate section.

- Enter the Date of the qualification test.

- Include the Reference WPS No (Welding Procedure Specification Number).

- Specify the Code or Specification Used for the qualification.

- Indicate the Welding Process and Type, selecting from options such as Manual, Semiautomatic, Mechanized, or Automatic.

- State whether Backing was used or not.

- Fill in the Base Metal Spec/P or M-Number.

- Document the Plate/Pipe Thickness for both Groove and Fillet welds.

- Provide the Pipe/Tubular Outside Diameter for both Groove and Fillet welds.

- List the Filler Metal Specification No. and Classification No..

- Indicate the F No. and Diameter of the filler metal.

- Specify if a Consumable Insert was used.

- State whether Penetration Enhancing Flux was used.

- Document the Deposited Weld Metal Thickness.

- Fill in the Current/Polarity & Current Range, including type and range in amperes.

- Specify the Metal Transfer Mode (e.g., GMAW or FCAW).

- Provide details on Torch Shielding Gas Type and Flow.

- If applicable, include information about Root Shielding Gas and its flow.

- List the Test Position(s) (e.g., 1G, 2G, etc.) and the Qualified Position(s) (F, H, V, O, or All).

- Indicate the Vertical Progression (Uphill or Downhill).

- Document the Type And Figure No. for the mechanical test results, along with the results.

- Include the name of the Guided Mechanical Testing Conducted By and the Date.

- For Non-destructive examination results, fill in the Radiographic Results and Report No..

- Indicate who conducted the Radiographic Testing and who witnessed the welding.

- Complete the Visual Inspection section, noting if it passed or failed, including the reason for failure if applicable.

- Certify the record by confirming that the statements are correct and that the test welds were prepared, welded, and tested according to the specified requirements.

- Finally, include the Date Qualified, ATF Name and Number, and the signature of the individual filling out the form, along with their CWI No. (Certified Welding Inspector Number).