Blank Da 5988 E Form

Key takeaways

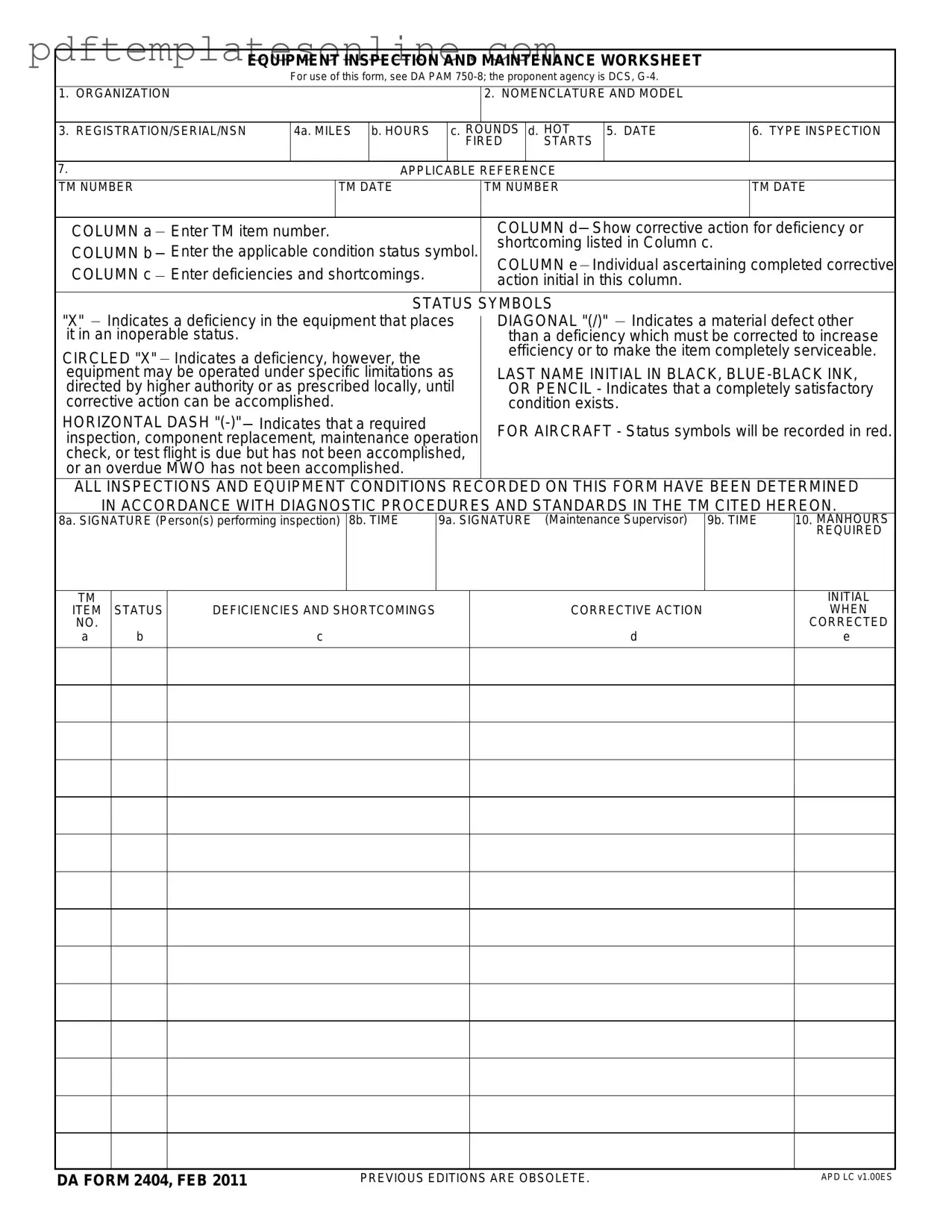

Filling out the DA 5988 E form accurately is crucial for effective aircraft maintenance and inspection. Here are some key takeaways to keep in mind:

- Purpose: This form serves as an equipment inspection and maintenance worksheet specifically for aircraft.

- Status Symbols: Use red ink to record status symbols that indicate the condition of the equipment.

- Essential Information: Make sure to include the organization, nomenclature, model, and registration or serial number in the designated sections.

- Inspection Details: Document miles, hours, fired rounds, and start shots accurately, as these metrics are vital for tracking usage and maintenance needs.

- Deficiencies: Clearly outline any deficiencies or shortcomings in Column c, as this helps identify issues that need immediate attention.

- Corrective Actions: In Column d, detail the corrective actions taken for each deficiency. This ensures a clear record of what has been done.

- Initials Required: The individual performing the inspection must initial Column e after completing corrective actions, providing accountability.

- Signature Section: Both the person performing the inspection and the maintenance supervisor must sign and note the time, confirming the inspection's completion.

- Diagnostic Procedures: All inspections and equipment conditions recorded must adhere to the diagnostic procedures outlined in the referenced technical manual (TM).

By following these guidelines, you can ensure that the DA 5988 E form is filled out correctly and effectively supports aircraft maintenance efforts.

Common mistakes

Filling out the DA 5988 E form is crucial for maintaining accurate records of equipment inspection and maintenance. However, many individuals make common mistakes that can lead to confusion and inefficiencies. Here are seven frequent errors to avoid.

One of the most significant mistakes is failing to provide complete information in the required fields. Each section of the form, from the organization name to the equipment's registration number, must be filled out thoroughly. Incomplete entries can result in delays in processing and may lead to miscommunication regarding the equipment's status.

Another common error is using incorrect ink or pencil for signatures. The instructions clearly state that signatures should be in black, blue-black ink, or pencil. Using other colors can create issues with legibility and may not be accepted by reviewing authorities, potentially causing delays in the approval process.

Many people also overlook the importance of accurately entering deficiencies and shortcomings in Column c. This section is critical for identifying issues with the equipment. Failing to specify these problems can lead to inadequate maintenance and unresolved operational challenges, which may affect overall equipment performance.

Additionally, neglecting to record the corrective actions taken in Column d is a frequent oversight. This column serves as a record of what has been done to address the identified deficiencies. Without this information, it becomes difficult to track the history of maintenance and repairs, which can complicate future inspections.

Another mistake involves not initialing the corrective actions in Column e. The person who verifies that the corrective actions have been completed must provide their initials. Failing to do so can raise questions about whether the necessary steps were taken, leading to potential accountability issues.

Furthermore, missing the signature and time entries for both the person performing the inspection and the maintenance supervisor can cause significant problems. These signatures serve as a verification of the information provided and ensure that accountability is maintained throughout the inspection process. Without them, the validity of the form may be questioned.

Lastly, not adhering to the status symbols outlined in the form can lead to misinterpretation of the equipment's condition. Each symbol has specific meanings that must be understood and applied correctly. Misusing these symbols can result in equipment being deemed operational when it is not, posing safety risks and operational challenges.

By being aware of these common mistakes and taking steps to avoid them, individuals can ensure that the DA 5988 E form is filled out accurately and efficiently, ultimately leading to better equipment management and safety.

Misconceptions

Misconceptions about the DA 5988 E form can lead to confusion and improper usage. Here are ten common misunderstandings along with clarifications:

- It is only for aircraft. While the form includes specific instructions for aircraft, it is applicable to various types of equipment and vehicles used by the military.

- Status symbols are optional. In reality, status symbols are crucial for indicating the operational status of equipment. They must be accurately recorded to ensure safety and compliance.

- Only maintenance supervisors can fill it out. Any qualified personnel can complete the form, as long as they are authorized to perform inspections and document findings.

- Deficiencies are not serious if they are marked with a circled "X." A circled "X" indicates that there are limitations on the equipment's operation, but it still requires attention to ensure full serviceability.

- The form is only for recording deficiencies. The DA 5988 E is also used to document corrective actions taken, which is essential for maintaining accurate maintenance records.

- Inspection dates are not important. The date of inspection is critical. It helps track maintenance schedules and ensures compliance with operational readiness standards.

- All corrective actions must be completed before the form can be submitted. While corrective actions are important, the form can still be submitted with notes on pending actions, as long as they are documented.

- Handwritten entries are not acceptable. Handwritten entries are permitted, but they must be clear and legible. Using black or blue-black ink is required for official documentation.

- Once submitted, the form cannot be altered. Corrections can be made, but they should be documented properly to maintain the integrity of the records.

- The DA 5988 E form is the only document needed for maintenance. It is one part of a larger system of documentation and should be used in conjunction with other forms and manuals for comprehensive maintenance management.

Understanding these misconceptions can help ensure that the DA 5988 E form is used effectively and correctly, promoting better maintenance practices and equipment readiness.

Dos and Don'ts

When filling out the DA 5988 E form, attention to detail is crucial. Here are some important dos and don’ts to ensure accurate and effective completion.

- Do use black or blue-black ink for signatures to ensure clarity.

- Do record all deficiencies and shortcomings clearly in Column C.

- Do ensure that all applicable reference TM numbers are entered correctly.

- Do have the individual performing the inspection initial in Column E after corrective actions are completed.

- Do indicate the correct status symbols as outlined in the instructions.

- Don't leave any section of the form blank; each part must be completed.

- Don't use pencil for signatures; this can lead to issues with legibility.

- Don't forget to document the time for both the inspection and maintenance supervisor signatures.

- Don't misinterpret the status symbols; ensure you understand their meanings before marking.

- Don't submit the form without reviewing it for accuracy and completeness.

Other PDF Forms

Nc4p - Line 1 of the NC-4 allows employees to specify the number of allowances they are claiming based on the worksheet.

Puppy Health Record - Record the timing of weaning from mother’s milk.

When dealing with financial transactions, utilizing a California Promissory Note form is essential for establishing clear terms of repayment. This form acts as a legal safeguard, ensuring both lenders and borrowers understand their obligations. To easily access and customize such documents, individuals can refer to California PDF Forms, which provides useful resources for creating a comprehensive promissory note tailored to specific needs.

Claim Exemption From Withholding - Record the date of the evaluation for reference.

Detailed Guide for Writing Da 5988 E

After gathering the necessary information, the next step involves accurately completing the DA 5988 E form. This form is essential for documenting equipment inspection and maintenance activities. Following the outlined steps will ensure that all required information is captured correctly.

- Organization: In the first section, write the name of the organization responsible for the equipment.

- Nomenclature and Model: Specify the equipment’s nomenclature and model number.

- Registration/Serial/NSN: Enter the registration number, serial number, or National Stock Number (NSN) of the equipment.

- Miles, Hours, Fired Rounds, Start Shot: Fill in the appropriate measurements for miles (4a), hours (4b), fired rounds (4c), and start shot (4d).

- Date: Indicate the date of the inspection in the designated space.

- Type Inspection: Specify the type of inspection being conducted.

- Applicable Reference TM Number: List the Technical Manual (TM) number relevant to the inspection.

- TM Date: Record the date of the TM referenced.

- Deficiencies and Shortcomings: In Column c, detail any deficiencies or shortcomings identified during the inspection.

- Condition Status Symbol: Enter the applicable condition status symbol in Column b, based on the findings.

- Corrective Action: In Column d, describe the corrective action taken for each deficiency or shortcoming.

- Initial When Corrected: In Column e, the individual who verifies the corrective action should initial this column.

- Signatures: Have the person(s) performing the inspection sign in 8a and record the time in 8b. The maintenance supervisor should sign in 9a and indicate the time in 9b.

- Manhours Required: Finally, document the manhours required for the corrective actions.